PLC optical splitter alignment packaging system is also known as optical fiber waveguide coupling system. It is widely used in semiconductor field and optical communication device development and production.

For example, in the field of optical communication devices, core-adjusting system can be divided into passive device core-adjusting system and active device core-adjusting system. Passive devices mainly refer to planar waveguide devices, isolators, beam splitters, etc. Active devices refer to LD and PDs. The common point of the two systems is that they need core-aligning coupling. The difference is that active devices need YAG welding to package, while passive devices mainly rely on UV glue to package.

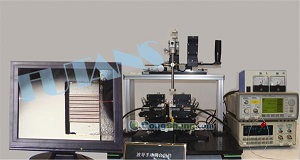

Our planar optical waveguide coupling packaging system employs advanced technologies such as machine vision, hybrid automatic alignment algorithm and precise adjusting frame to achieve the following four technical indicators: 1. High alignment accuracy of the system: the additional loss of the waveguide devices aligned by the system is less than 0.15DB; 2. The system has good repeatability: three-time alignment of the same waveguide device, and the alignment of each channel of the device. Loss variation is less than 0.05DB, 3. Time stability of the system: After alignment of waveguide devices and optical fibers, the loss of each channel of the device changes less than 0.05DB within 10 minutes. 4. System efficiency: After rough alignment of waveguide devices and optical fibers by means of CCD, the precise alignment time of each waveguide device is about 2 minutes.

Functionally speaking, the core-adjusting system can be divided into manual system, electric system and automatic system. Generally, the system consists of precision alignment unit, observation unit (visible and infrared), packaging unit (UV glue or YAG laser welding) and so on.

Futansi (Shanghai) Company sells its systems to customers, which are basically high-precision and high-performance system products built with foreign core products. In this respect, domestic products can not meet the high-precision requirements. Futansi (Shanghai) has rich experience in designing and installing a number of systems for customers. Because of the particularity of this system, many systems are designed according to the specific application of customers, so we have established the largest customer group of this system in China, and accumulated a lot of experience. At the same time, according to China's national conditions, without affecting the accuracy of the system, we localized the non-critical parts of the system, which greatly reduced the cost of the system.

At present, the packaging system of PLC optical splitter built by Futansi (Shanghai) Company with high precision six-dimensional adjusting frame has been recognized by many customers. Futansi (Shanghai) Company has a strong engineering and technical team. Engineers have many years of experience in Shenzhen, and cooperate with some localized components, such as fixture, observation unit, infrared unit, light source, intensity detection unit, UV dispensing unit and curing unit, we can achieve localization. The cost performance ratio has great advantages: Futansi (Shanghai) company designed the department. Under the condition of guaranteeing stability and precision, all the components except the key components imported from Japan have been localized, which can greatly reduce costs for domestic customers and enhance the competitiveness of enterprises. There are also great advantages in function: Futansi (Shanghai) company has designed a complete range of systems, complete functions; there are a variety of design schemes, such as manual, electric, semi-automatic, automatic, and so on. The application scope can also be multi-choice and directional design.

At present, the packaging system of PLC optical splitter built by Futansi (Shanghai) Company with high precision six-dimensional adjusting frame has been recognized by many customers. Futansi (Shanghai) Company has a strong engineering and technical team. Engineers have many years of experience in Shenzhen, and cooperate with some localized components, such as fixture, observation unit, infrared unit, light source, intensity detection unit, UV dispensing unit and curing unit, we can achieve localization. The cost performance ratio has great advantages: Futansi (Shanghai) company designed the department. Under the condition of guaranteeing stability and precision, all the components except the key components imported from Japan have been localized, which can greatly reduce costs for domestic customers and enhance the competitiveness of enterprises. There are also great advantages in function: Futansi (Shanghai) company has designed a complete range of systems, complete functions; there are a variety of design schemes, such as manual, electric, semi-automatic, automatic, and so on. The application scope can also be multi-choice and directional design.